Two Notre Dame undergraduates—one in the College of Engineering and the other in the College of Science—have teamed up with an orthopedic surgeon to develop an innovative device that repairs fractures in hip replacement patients while minimizing damage to tendons and muscles.

A common complication in hip replacement surgery is a fractured trochanter—the bony lump on the top of the femur where muscles attach. Devices and implants are available to fix fractures when surgeons access the back side of the hip, but fewer options exist for surgeons who opt for an anterior, or front-of-the-hip approach.

“Trochanteric fractures remain an unsolved problem with elevated rates of delayed healing and high rates of reoperation,” said orthopedic surgeon Dr. Justin LaReau (ND ’99). “They’re a significant source of frustration for patients and surgeons.

To help address this problem, LaReau patented a device called a “Direct Anterior Hip Replacement Trochanter Securement Apparatus” and recruited two Notre Dame students, Sam Thornton, a sophomore mechanical engineering major, and Molly Maxwell, a junior preprofessional studies major from the College of Science, to figure out the optimal way to secure and stabilize the device.

LaReau said that Notre Dame’s resources together with the students’ research advisor, Professor James Schmiedeler—an expert in both gait and biomedical research—and the quality and inquisitiveness of Notre Dame undergraduates, argued strongly for bringing his research questions to Notre Dame.*

Maxwell and Thornton both aspire to being orthopedic surgeons, so this research enables them to apply concepts they’ve learned in the classroom to actual medical problems.

Thornton uses his engineering background to tackle challenges like efficient force or load distributions in the hip and uses CAD to design testing components.

“This research project requires us to completely design our own tests from scratch,” said Thornton. “Being able to view the project as a whole, break it down into a series of objectives, and come up with designs to achieve those objectives—skills I developed in my Introduction to Design Thinking in Engineering class—has been extremely useful.”

Maxwell enlists her science background to review existing literature on hip replacement surgeries, study current protocol and hardware designs, and help brainstorm modifications to the testing system.

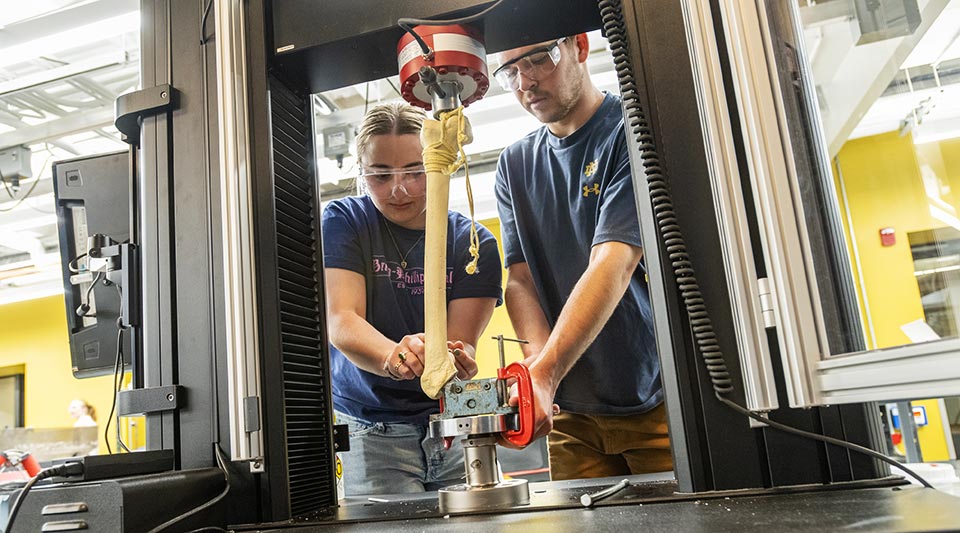

Using the artificial bones provided by Dr. LaReau and the Instron machine at the Engineering Innovation Hub, Maxwell and Thornton apply various forces— tensile, compression, flexural—to determine the best means of securing sutures to the apparatus. Next, they will 3D print their design concepts for anchoring sutures and retest them.

Ultimately, the goal is to stabilize the trochanter with sutures on the exterior of the bone, which are also anchored inside the bone. Thornton compares this approach to the way an acoustic guitar string is fastened at the bridge.

“I think our different niches interact really nicely during this project because it’s essential to keep a balance between an understanding of the human body and the fundamentals of mechanics,” said Maxwell. “Our brainstorming and troubleshooting are dependent on our different areas of expertise, but our success is a result of a collaborative approach.”

—Karla Cruise, Notre Dame Engineering; Photos by Wes Evard, Notre Dame Engineering; Diagram provided by Dr. Justin LaReau.

*Students utilized STRAND (Student Research @ Notre Dame), an online posting board, to secure this research opportunity. STRAND provides undergraduate students with a clear, scheduled, and equitable way to apply for research opportunities.